What is Nonwoven Needle Felt Filter Fabrics?

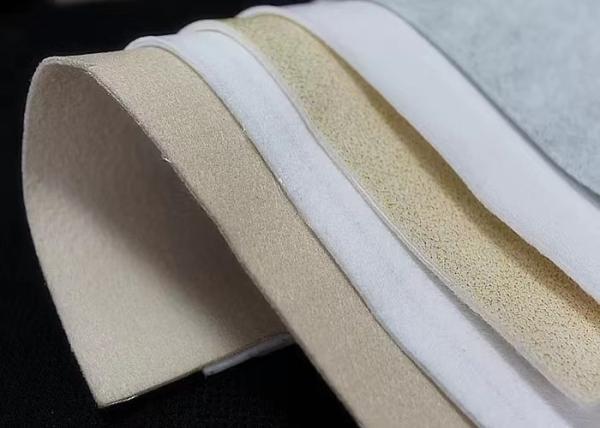

Needle felt is a kind of non-woven filter fabric specially used for

dust collector filter bags. It is a major filter material for

industrial air filtration and dust removal. The needle felt is made

of randomly arranged fibers needle punched on the scrim fabric,

after that the fibers are close-knitted to form a tortuous

three-dimensional stereo-structure, which is different from the

traditional woven filter cloth composed of warp and weft yarns. It

makes dust particles adhere to the surface of the filter material

and form an initial layer of dust ( Filter cake), with the

remarkable characteristics of small pore size, high filtration

efficiency and low air resistance, greater air permeability and

excellent dust particle capture.

Needle felt for dust collector filter bags

What is needle felt filter fabrics features and advantages?

The irregular fibers in the needle felt filter fabrics are arranged

in three dimensions, which could give full play to the dust capture

capacity

This structure easy to form the dust filter cake layer in the

initial of filtration production, and is no straight pore after

dedust. It makes the air filter bags has a high and stable dust

collection efficiency.

The statical dust capture rate of needle felt filter cloth could up

to 99.5% ~ 99.99%

The porosity of needle filter felt is as high as 70% ~ 80%, which

is 1.6 ~ 2.0 times of woven filter fabrics, it gets larger air

permeability and lower air resistance

Main Characteristics of a Non-woven Needle Filter Felt:

Physical characteristics

Weight, the most rudimental and important data of a needle

felt,also is an important factor affecting the price of the filter

fabrics

Thickness, too thick will lower the fabric strength and filtration

efficiency, meanwhile too thin will lower the wear resistance and

increase air resistance

Air permeability, the crucial parameter of a filter fabric

Tensile strength, an important parameter to determine the quality

of a needle felt filter fabric

Breaking strength, indicate the robustness of a needle felt filter

cloth

Wear resistance, include planar wear, flexual wear and crease wear,

it depends on material property, fiber shape and fabric structure

Chemical characteristics

Temperature resistance, include continuous working temperature and

surge temperature, one of the most important parameter to choose

the suitable needle felt for the dust collector bags

Abrasion resistance,

Dust removal characteristics

1.Resistance coefficient of clean filter material

2.Statical dust removal rate

3.Dynamic dust removal rate

4.Dynamic air resistance

5.Drag coefficient

6.Dedusting rate

Specific characteristics

Anti-static

Water & Oil resistance

Production process

After Treatment

1.Heat setting, the heat setting of needle felt is to eliminate the

stress in the fabric to obtain a stable dimension and smooth

surface, which are important to the reliability and service

lifetime of the air filter bags.

2.Sing, burn off the floating fibers on the surface of the needle

felt filter material to make the surface smoother and easy to dust

removal.

3.Calendar, hot calendering makes the surface of the needle felt

filter cloth smoother, with uniform thickness and air permeability.

Although the initial resistance will be slightly bigger, it remains

the particles on the surface, the dust does not easily enter the

deep layer and is easier to dedust. This helps to reduce the air

resistance of the bag housing dust collector, and increase

filtration efficiency and service life of the filter bags.

Coating, including water & oil resistance coating and PTFE coating

treatment, It avoids agglomeration on the surface of the filter

fabrics when there is condensation in the bag filter housing.

4.PTFE treatment, including PTFE dipping and PTFE membrane

PTFE impregnation(dipping) treatment reduces the fabric pore size,

improves the filtration efficiency, moreover, enhance the heat

resistance, corrosion resistance, oxidation resistance and abrasion

resistance properties of the needle felt filter fabrics.

5.PTFE membrane is an ideal solution to control the pollution PM2.5

Avaliable Needle felt for your option

Polyester needle felt / P84 needle felt

PPS (Ryton) needle felt / Fiber glass needle felt

Metamax (Nomex) needle felt / Polypropylene (PP) needle felt

Acrylic needle felt / PPS+PTFE felt

PTFE needle felt / Aramide + PTFE felt